Table of Contents

Automation:

With the pressing need for increased productivity and the delivery of end products of uniform quality, industry is turning more and more towards computer-based automation. There are several examples of automation one comes across daily, simple examples being sewing machines, packaging machines.

Such machines are generally equipped to perform in a specific way or to execute specific tasks. A sewing machine is designed to produce specific stitch lengths and likewise a packaging machine is designed to wrap a specific size of the product. When product sizes change some parts of the machine are to be manually changed to accommodate the new size. Such machines are essentially designed to package millions of products of a specific size and are hence special purpose machines.

At the present time, most of the tasks are carried out by such special purpose machines designed to perform predetermined functions in a manufacturing process. The inflexibility and generally high cost of these machines, often called hard automation systems, have led to a broad-based interest in the use of such automation systems (known as flexible automation systems), which are capable of performing a variety of manufacturing functions in a more flexible working environment and at lower production costs. More recently there is a demand for variety.

The good examples for the products having wide variety and flexibility could be television sets, mobile phones etc. Handling such varied and flexible tasks are not only time consuming, but also requires skill. Human beings, unlike machines can not only handle tools and products of different sizes and shapes but are also capable of executing a variety of tasks. Engineers have often sought similar capabilities in machines and this has been possible now with the availability of inexpensive microprocessors. Used in conjunction with special servo-motors, actuators and sensors, the microprocessor has revolutionized automation.

Robotics:

The word robot originated from the Czech word robota, meaning work. Webster’s dictionary defines robot as “an automatic device that performs functions ordinarily ascribed to human beings”. With this definition, washing machines may be considered robots.

A definition used by the Robot Institute of America gives a more precise description of industrial robots: “A robot is a reprogrammable multi-functional manipulator designed to move materials, parts, tools or specialized devices through variable programmed motions for the performance of a variety of tasks”.

However, one cannot expect a given robot to execute any arbitrary task or handle any product. Sometimes it may be beneficial to redesign the product to enable robots to handle them with ease. A well-known example of designing a product to suit robots is the SONY “Walkman” which has been designed for ease of assembly by robots.

- An industrial robot is a general-purpose computer-controlled manipulator consisting of several rigid links connected in series by revolute or prismatic or both joints. One end of the chain is attached to a supporting base while the other end is free and equipped with a tool to manipulate objects or perform assembly tasks. The motion of the joints results in relative motion of the links.

- Mechanically, robot is composed of an arm (or mainframe) and a wrist subassembly plus a tool. It is designed to reach a workpiece located within its work volume.

- The work volume is the sphere of influence of a robot whose arm can deliver the wrist subassembly unit to any point within the sphere.

- The arm subassembly generally can move with three degrees of freedom. The combination of the movements positions the wrist unit at the workpiece. The wrist subassembly unit usually consists of three rotary motion – pitch, yaw and roll.

Historical Developments:

1921 – The word robot was introduced into the English language by the play-wright Karel Capek in his satirical drama, R.U.R (Rossum’s universal robots). In this work robots are machines that resemble people but work tirelessly.

Late 1940 – Research programs were started at the oak ridge and Argonne national laboratories to develop remotely controlled mechanical manipulators for handling radioactive materials. These systems were of master-slave type.

Mid 1950 – George C. Devol developed a device “programmed articulated transfer device”.

1954 – Devol & Engleburger – establish Unimation corporation.

1959 – First industrial robot – developed by Unimation corporation.

1961 – Robots are used in die casting application.

1962 – H. A. Ernst – development of a computer controlled mechanical hand with tactile sensors.

1968 – AGVs (Automated Guided Vehicles) implemented.

1970 – Stanford arm developed.

1974 – Cincinnati Milacron – developed their first industrial robot “The Tomorrow Tool (T3). It could lift over 100 lb as well as track moving objects on an assembly line.

1979 – SCARA robot for assembly developed in Japan.

Application Areas of Robots:

Industrial robots are widely used in manufacturing and assembly tasks, such as material handling, spot / arc welding, parts assembly, spray painting, loading and unloading NC machines, space and undersea exploration, prosthetic arm research and in handling hazardous materials.

Broadly these application areas can be classified into three categories;

- Hazardous Environment – such as handling of fuel and radioactive material in nuclear power plants and in space and under water operations.

- Repetitive Environment – such as spray painting, assembly operations, loading and unloading operations.

- Environment in which Product Variety is changing frequently – such as television sets, mobile phones, camera etc.

Today robot finds applications in industries, medical and other fields. For example, in eye surgery (replacement of retina), where a cylindrical portion needs to be replaced, the operation is best done by robots. Mobile robots like walking machines, hopping machines are examples of robots, and so also are robotic aircraft and ships. Nuclear and power plants use fish like robots which move inside pipes for purpose of inspection.

Oil and Gas

Oil and gas companies are using robots to accomplish dangerous drilling tasks and eliminate the risk to human life. Robots do inspection of the site and create a 3D map of the site using sensors so that humans can safely navigate through these environments. Roughnecking robots are used to install drill pipes in complex environments, such as oil-bearing rocks and oceans. The robotics industry has advanced so much that it is now possible to automate entire oil rigs, eliminating the need for humans to live on and work on them. Since robots can work on repetitive tasks, human employees can work on more value-added functions. Robotics has also decreased the amount of downtime during and between work tasks.

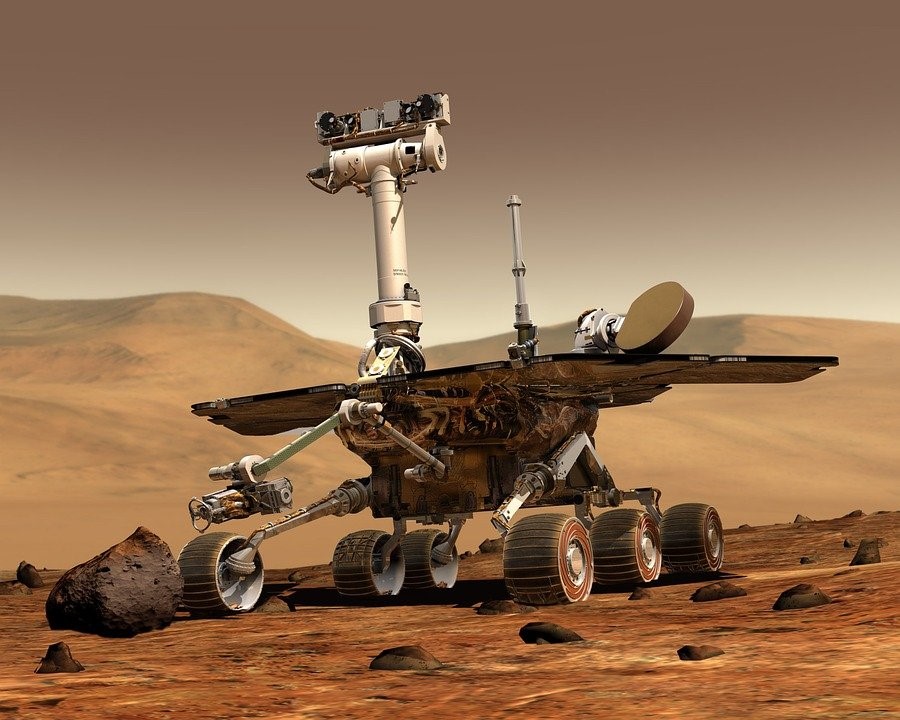

Robotics In Space

For a long period of time, robotics has been used in space stations. They are being used to probe and explore places that are not accessible to humans as no oxygen is available over there. They can also withstand high temperatures, exposure to radiation and can perform tasks over a long period of time without direct human supervision. The outer planets, such as Uranus, Neptune, and Jupiter, are all too far away from Earth to be reached with current crewed spaceflight technology. To conduct scientific research and measurements, a robotic aircraft with no human control or design is used.

Many space missions are more suited to tally robotics rather than crew due to their lower costs and low risk factor, as in the case of Venus and Mars. They can provide data such as photographs, images, and surface topography. They are also capable of sending back signals related to spacecraft health. They are also capable of taking samples for examination. It can assemble a structure and it can move around like an astronaut. Although robots are very expensive to design and produce, the fact that they are lost in space is always better than the loss of astronauts.

Search And Rescue

In the last few decades, natural disasters have increased many-folds. Every year, over 100,000,000 people are affected by natural disasters. Government companies and organisations are working to keep this tragic death as low as possible. Robotics is very useful in search and rescue options. There are numerous benefits of robotics in disaster response. They can openly fit into places where humans can’t, they can operate in environments where humans can’t, they can work tirelessly, and most importantly, they are replaceable. They can also be sent to places which are too dangerous for human rescue workers, which is often the case in disaster areas. They can work faster than humans. And this can create a difference between life and death.

Deep Sea Robotics

Applications of the Recirculatory Aquaculture System (RAS) for underwater and deep-sea activities are vast. One such application is deep diving and exploration activities in ice-covered waters. In the absence of GPS signals in these waters, localization of the robots was achieved using acoustic beacons fixed onto ice along the intended path of the vehicle. They can be deployed both from land and sea. They are also being used for dam inspections and long-term deep-sea observations using underwater docking stations for wireless charging.

Conclusion

We can conclude that there are many tasks which are performed by robots and are quite risky if done by humans. Use of robotics has also improved efficiency and reduced the cost of the project. Still, there are many grounds where humans are superior, and robotics cannot be used. Further research is underway to improve the functionality of the robots.

Want to know more about making a career in the field of Robotics and Automation, Click here to Book your FREE Consultation Call with our Head Mentor

In case, if you feel that we have missed something important in this article and needs to be included for its betterment, feel free to share your suggestions with us through comments or mail us at rudrasupport@gyaannirudra.com.

Stay connected with us to be aware about the different career or business opportunities in other fields as well.

Wishing you all a splendid and exponentially growing career journey ahead.

I am Adesh Vats presently pursuing my MBA in Business Analytics. I am an optimistic person who believe more in practical than in theoretical. Exploring the different places and taking photographs is my hobby.